Value Add Services

Laser Ablation

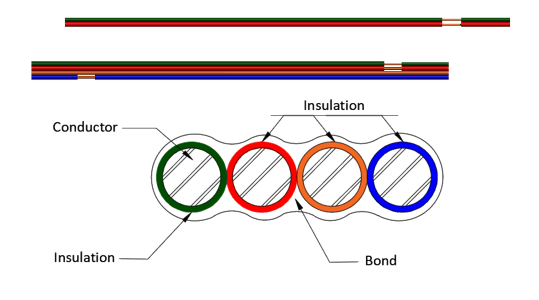

Enamels may be stripped into small “windows” at precise lengths in a reel to reel process that allows for continuous length of wire delivered on spools for further processing. Advances in the development of interconnects in the medical device market have resulted in novel ribbon cable assemblies where laser ablating can speed up and simplify the process of making connections of the cable.

When stripping a wire (creating laser ablated wire), it is necessary to cut right around the wire circumference. This is usually achieved by making a cut from opposite sides. For very thick wires it may be necessary to cut right around the circumference by spinning the wire or the laser beam – but for thinner wires (<5 mm / 0.2″ diameter) – it is enough to cut from two sides and have the two cuts join together. For example, see the diagram below.

Straightening and Cutting

MWS offers wire cutting and wire straightening services. We straighten and cut wire in a wide variety of sizes, lengths and materials – meeting tight tolerances on length and straightness. Straightness is done through a mill or rotary system and is measured by the maximum curve between the wire and a flat reference surface. Cutting is offered with chamfer or radius ends and controlled to eliminate deformity and cut off burrs.