MWS Wire /

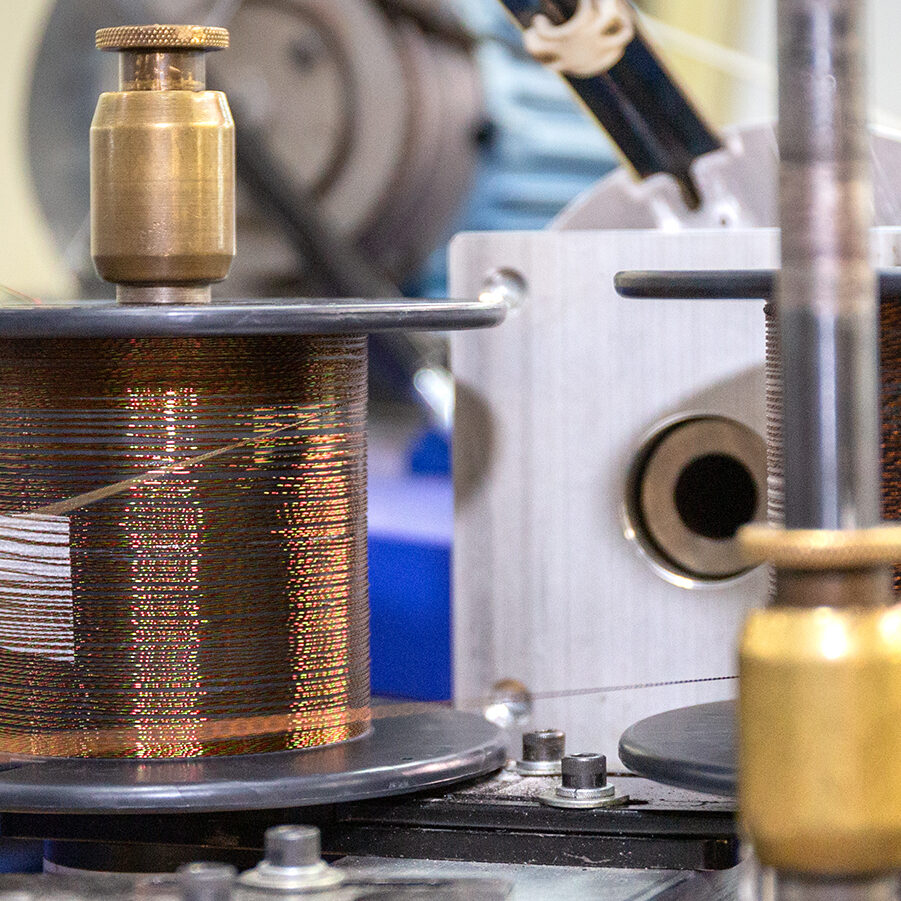

MWS Wire is the Leader in Aerospace Wire Manufacturing

The aerospace and defense industries have long turned to MWS Wire for custom aerospace wire solutions to sophisticated challenges. Avionics, Electronics, Flight Controls, GPS, Navigation Systems, Probes, Sensors, Weather Systems, and Deep Space Exploration all require the kind of fine and ultra-fine precision wire produced by MWS.

Polyimide ML Insulation is a key to Aerospace Wire performance and longevity in space

The uses for Polyimide ML insulation (thermal class 240°C) are high-temperature continuous duty coils, hermetically sealed relays, and fractional and integral HP motors. This insulation is primarily used in the aerospace industry due to its minimal outgassing property.

Why Choose MWS for your Aerospace Wire Needs?

Based in the USA

High Quality In-House Testing

Founded in 1968

Dedicated Customer Service Representative

Polyimide ML Applications & Features for Aerospace Wire Applications

Because of its thermal insulation and radiation resistance properties, Polyimide (ML) is used to wind coils on satellites, spacecraft and launch vehicles. Other uses include avionics, navigation, flight controls, wing movement, and collision avoidance.

Electronic applications – Polyimide (ML) film is ideal for high heat environments, such as wheel speed sensors, brake control systems and for the majority of applications in all Aerospace market segments.

Polyimide Varnish for Heat-Resistant Insulation Coating: This resin not only has excellent heat stability, but also great mechanical and electrical characteristics and reliability, thus achieving a long history of use and popularity. These applications continuously are expanding to include use in insulated covers for heat-resistant wires, as well as parts used in airplane production and industrial equipment.

Minimal Outgassing: One of the top benefits of MWS Wire's Polyimide ML for Aerospace Wire includes minimal outgassing. The Polyimide insulation without lube offers the least amount of outgassing available.

Top Features of Pyre-M.L. heat membrane:

- High strength and elasticity

- Heat and cold resistance

- Can be used at a wide range of temperatures: between -269°C and 400°C (continuous service temperature = 260°C)

- High-voltage insulation properties

- Chemical resistance / Oil resistance

- Radioactive resistance

- Dimensional stability

- Nonflammable

Aerospace Wires Inventoried or Produced by MWS

- Copper Magnet Wire

- No Lube Magnet Wire

- Litz Wire

- Plated Wire (Gold, Silver, Tin, Tin-Lead, Nickel)

- Bondable Magnet Wire

- Insulated Wire (All conductor types)

- Ribbon Wire

- Square Magnet Wire

- Rectangular Magnet Wire

- Microsquare Magnet Wire® (15 AWG and finer)

- Multifilar® Magnet Wire

- Twistite Magnet Wire®

- EC Aluminum 1350 Magnet Wire

- Certified OFHC Copper

- OFHC Copper

- ETP Copper

- Copper Clad Steel and Copper Clad Aluminum

- Copper Alloy Wire (Silver Bearing, Beryllium Copper, Phosphor Bronze)

- Pure Nickel Wire (Nickel 205, Nickel 270)

- Nickel Alloy Wire (Monel 400, Inconel x 750, Inconel 600)

- Stainless Steel Wire (302/304, 316, 321 and 17-7 PH)

- Nichrome Wire (MWS-675 or MWS-650)

- Precious Metal Wire (Platinum, Gold, Silver)

- Refractory Metals (Niobium, Tungsten)