MWS Wire /

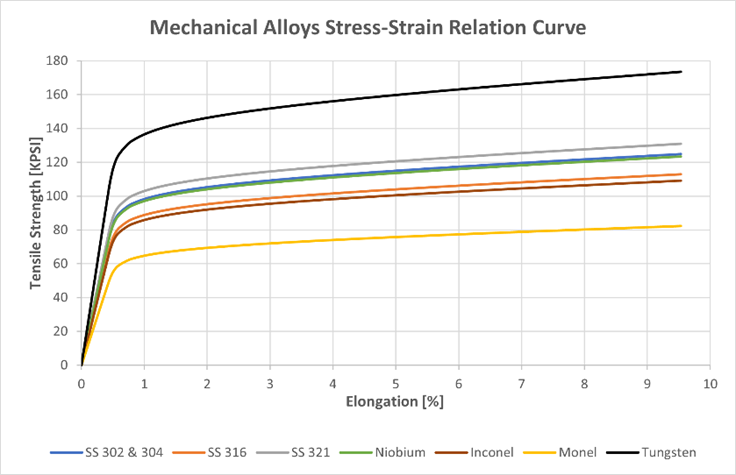

When selecting wire for mechanical applications, it is important to start with the key physical attributes needed for the specific application. These can be properties like temperature resistance, corrosion resistance, tensile strength, and conductivity/resistivity. We recommend a three-step process:

- Initial screening based key physical attributes.

- Full analysis of the physical properties of the selected material.

- Final screening on specific material properties, material, and forming costs.

Know what you need?

Mechanical Alloys Data Table

| MATERIAL | COMPOSITION | RESISTIVITY | COEFFICIENT OF LINEAR EXPANSION (0-100°C) | TENSILE STRENGTH NOMINAL (KPSI) | DENSITY | MAGNETIC ATTRACTION | MELTING POINT | |

| (%) | OHMS/CMF | µm/m | SOFT | HARD | lb/in³ | (°C) | ||

| #302 Stainless Steel | Cr 18, Ni 9, Mn 2, Si 1, C .12, N .1, P .045, S .03, Bal Fe | 433.1 | 17.3 | 125 | 330 | 0.290 | None | 1,410 |

| #304 Stainless Steel | Cr 19, Ni 9.25, Mn 2, Si 1, C .08, N .1, P .045, S .03, Bal Fe | 433.1 | 17.3 | 125 | 330 | 0.290 | None | 1,425 |

| #316 Stainless Steel | Cr 17.25, Ni 12, Mo 2.25, Mn 2, Si 1, C .07, N 0.1, P .045, S .03, Bal Fe | 444.6 | 15.9 | 113 | 260 | 0.290 | None | 1,387 |

| #321 Stainless Steel | Cr 18, Ni 10.5, Mn 2, Si 1, Ti .4, C .08, P .045, S .03, Bal Fe | 433.1 | 16.6 | 130 | 250 | 0.290 | None | 1,387 |

| Inconel* 600 | Ni 72, Cr 15.5, Fe 8, Mn 1, Cu .5, Si .5, C .15, S.015 | 619.6 | 11.8 | 110 | 205 | 0.306 | None | 1,384 |

| Inconel* X-750 | Ni 70, Cr 15.5, Fe 7, Ti 2.5, Mn 1, Nb .75, Al 0.7, Si .5, Cu .5, C .08, S .01 | 733.9 | 12.0 | 145 | 225 | 0.299 | None | 1,410 |

| Monel* 400 | Ni 63-70, Cu 28-34, Fe 2.5, Mn 2, Si .5, C .3, S .024 | 329.0 | 13.5 | 83 | 163 | 0.318 | Weak | 1,325 |

| Niobium | Ta .20, W .05, O .025, Hf .02, C .01, N .01, Al .005, Balance Nb | 91.43 | 7.0 | 125 | 240 | 0.310 | Strong | 2,477 |

| Tungsten | W 99.95 min, Thorium balance | 33.08 | 4.3 | 175 | 500 | 0.697 | Weak | 3,410 |

* Registered trademark of INCO family of companies

Product Spotlight

Stainless Steel

Stainless steel is a strong, versatile, and corrosion-resistant material common to the industrial, aerospace, and automotive industries. This material is also used extensively in the medical field where its anti-corrosive and durable properties are ideal for sterile environments.

Stainless Steel Wire Type 302

UNS S30200

Chromium: 17% -19%

- Often used for springs due to its excellent combination of physical properties and corrosion resistance.

- Stronger than type 304 but with lower corrosion resistance.

Available in:

- Condition A: Soft or annealed temper per ASTM A580

- Condition B: Spring temper per ASTM A313

Stainless Steel Wire Type 304

UNS S30400

Chromium: 18% - 20%

- Most common overall type used in a variety of applications including tie wire, lock wire, safety wire, cold heading wire, weave wire mesh, and screen wire.

- Lower strength than type 302 but with higher corrosion resistance.

Available in:

- Condition A: Soft or annealed temper per ASTM A580

- Condition B: Spring temper per ASTM A313

Stainless Steel Wire Type 316

UNS S31603

Chromium: 17% -19%

- This type is known for its non-magnetic properties.

- Added molybdenum gives this material high creep strength at elevated temperatures.

- Generally better than types 302, 304 and 321 at resisting pit and crevice corrosion.

Available in:

- Condition A: Soft or annealed temper per ASTM A580

- Condition B: Spring temper per ASTM A313

Stainless Steel Wire Type 321

UNS S32100

Chromium: 17% -19%

- Commonly utilized in applications where welding is used in fabrication or where heat is encountered as a service condition.

- Stabilized with titanium to prevent sensitization. (Carbide precipitation and intergranular corrosion.)

Available in:

- Cold rolled

- Annealed

- Tested to AMS 5510

Nickel Alloys/ Monel* Wire

Monel is a group of nickel alloys, primarily composed of nickel and copper, with small amounts of iron, manganese, carbon, and silicon. Stronger than pure nickel, Monel alloys are resistant to corrosion by many agents, including rapidly flowing seawater. These alloys can be fabricated readily by hot- and cold-working, machining, and welding. Nickel based alloys are used in RTD sensors, resistors, rheostats, voltage control relays, heating elements, potentiometers, and other components.

*Inconel and Monel are registered trademarks of Inco family of companies

Inconel 600

UNS S30200

Nickel: 72%

- Resists corrosion and oxidation to 2150°F.

- Provides springs with high resistance to corrosion and heat up to 750°F.

- Tough and ductile down to -310°F

- Nonmagnetic, easily fabricated and welded.

- Used for structural parts, cathode ray tube spiders, thyratron grids, sheathing, tube supports, spark plug electrodes.

Available in:

- Annealed and hard per ASTM B166

Inconel X-750

UNS N07750

Nickel: 70%

- Age hardenable, nonmagnetic, corrosion and oxidation resistant.

- High creep-rupture strength to 1300°F.

- Heavy cold working develops tensile strengths of 290,000 PSI.

- Stays tough and ductile to -423°F.

- Resists chloride-ion stress-corrosion cracking.

- For springs operating to 1200°F and tube structural parts.

Available in:

- Annealed and hard per ASTM B637

Monel 400

UNS N04400

Nickel: 63%-70%

- Operating temperatures up to 1050°F

- Maintains mechanical properties even at sub-zero temperatures.

- Melting point is 2370 - 2460°F

- Can be hardened only by cold-working.

- Used in corrosive environments with highly variable temperatures.

- This material's toughness over a considerable range of temperatures and excellent resistances allows it to be used in corrosive or unstable environments.

Available in:

Annealed and hard per ASTM B164

Refractory Metals

Refractory metals are a class of metals that have very high melting points, high hardness, high density, and resistance to heat, wear, and corrosion. They are mostly used in applications that require high-temperature stability, strength, and durability. MWS offers refractory metals listed below in bare and insulated in different sizes.

Niobium Wire

UNS R04300 Type 1 (Pure Grade) |

UNS R04210 Type 2 (Commercial Grade)

- High melting point (4491 °F) can withstand extreme temperatures and cyclic stress loads.

- Tensile strength (up to 240 Kpsi),

- Excellent conductivity (9.09 W/ft °F)

- Superconductive when cooled below critical temperature (typically around -444 °F)

- Biocompatibility and corrosion resistive properties make it ideal for medical purposes.

- Used in MRS, NMR and MRI machines.

- Aerospace and Nuclear applications

Available in:

Annealed and hard per ASTM B392

Tungsten Wire

UNS R07005

- Tungsten is a naturally paramagnetic material known for its high strength and durability

- The metal with the highest melting point (6170°F) and the highest tensile strength of 175KPSI (annealed) and 500 KPSI (hard).

- Used for filaments, electrodes, alloys, and catalysts.

- Highly used in the aerospace and nuclear industries as tools or lighting elements where durability is critical

Available in:

- Annealed and hard per ASTM F288

Special Processes

Ask a sales representative about any special temper or wire finish.

Wire is available in sizes 14 - 44 AWG with the following options:

- Soft/Hard Temper

- Bare

- Insulated

- Shaped

- Plated

- Bondable

Mechanical Alloys Wire Data

Need more info about chemical composition? See our Data Sheet.

Looking for something specific?

We probably have it in stock. If we don't, we can make it faster than you'd think!

Why Choose MWS?

Quick and Right Answers.

We invest heavily in our customer service and engineering team so that we can give you the right answers and the most effective customized solutions. Our success, as well as our very purpose, is directly linked to the long-term satisfaction of our customers using our wire products.

Unrivaled Availability, Low Minimum Order Quantity, and Quick Delivery.

MWS has one of the largest inventories of stainless-steel wire and other wire products. We provide wire from 1/4lb to 50lb spools. Ninety percent of our stock orders go out within a week. Short production runs and quick turnarounds are our specialty.

Pre-cut Wire Lengths and Other Custom Orders.

We can provide straight wire cuts from one inch to 6-foot lengths holding the tolerances you require for your specific application. Need shaped wire? We have a variety of special shapes including square wire, flat wire, and ribbon wire. Special coatings and finishes are available as well.

Headache Free Compliance Documentation.

Let us help you satisfy your customer's needs for clear and comprehensive compliance documentation including RoHS, REACH, DFARS, MADE IN USA, USMCA, etc. Chemical and physical testing reports are also available upon request.

Let Us Manage Your Inventory for You.

With 40,000 sq. ft. of warehouse space and thousands of products in stock, inventory management is our specialty. It doesn't have to be yours. Whether it's same day shipment from inventory or producing a wire to meet just-in-time schedules, we can get what you need when you need it. Ask about scheduled shipments synchronized to work with your inventory control, JIT, or Kanban system.