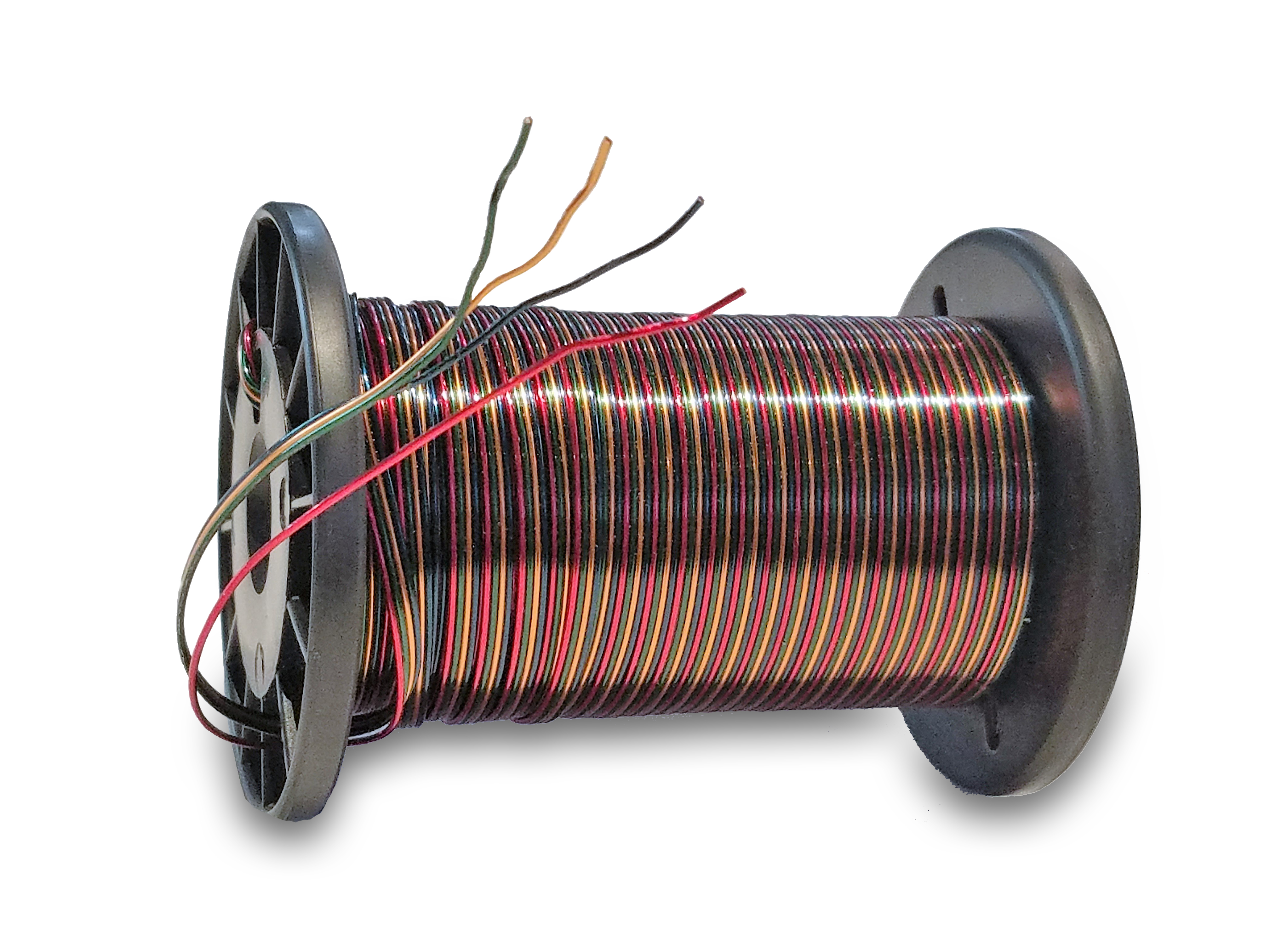

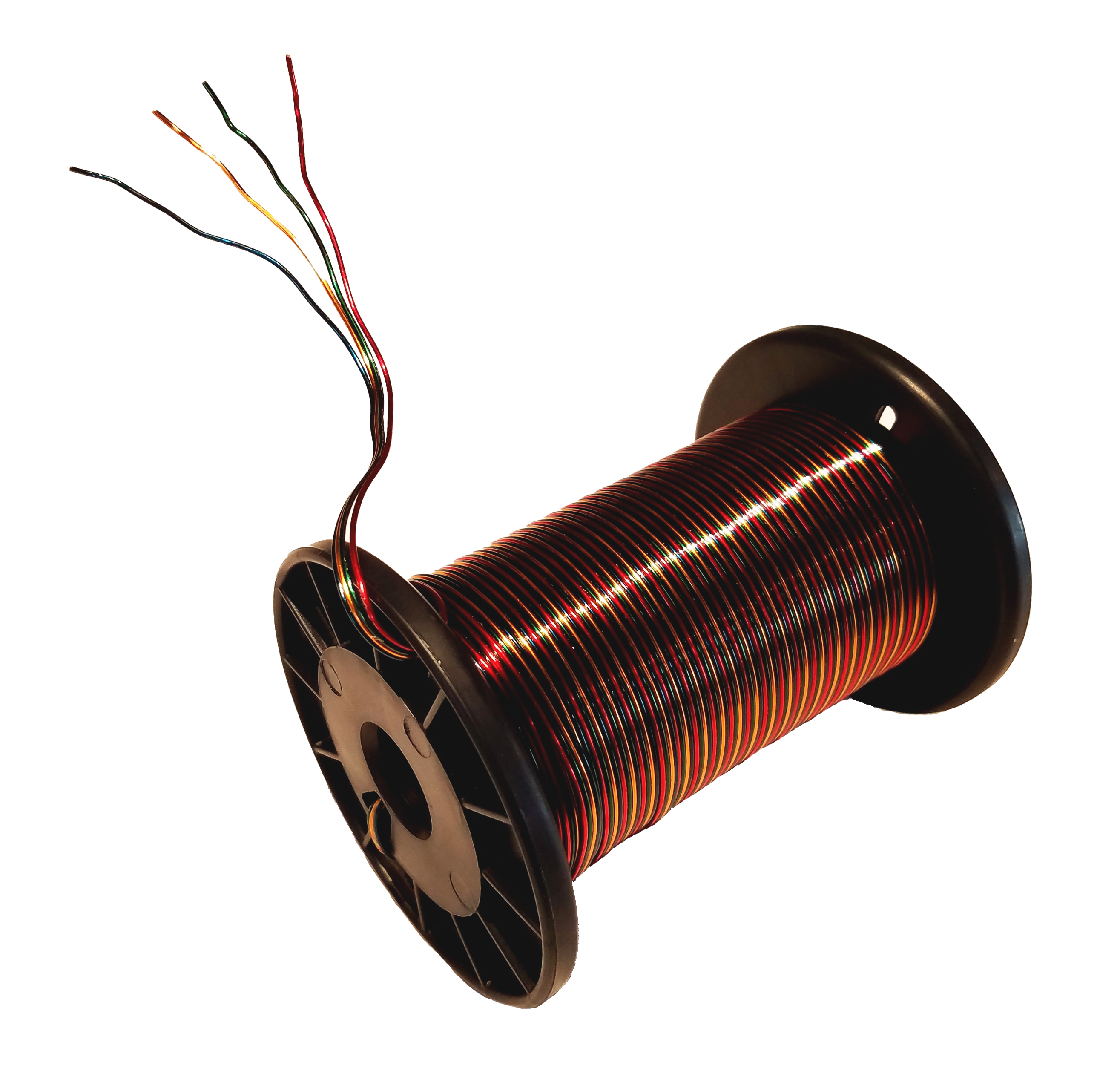

Multifilar® is a parallel bonded magnet wire with more consistent capacitance and impedance characteristics that has been produced exclusively by MWS since the 1970s.

Where constant alignment of multiple strands is an advantage, Multifilar® Magnet Wire is the right choice. Its parallel-bonded, color-coded construction offers benefits for many applications.

Engineers should specify Multifilar® when concerned with space, weight, and reliability. Where consistent capacitance and impedance characteristics are required, Multifilar® magnet wire outperforms windings using two separate magnet wires.

Production users benefit from increased layer winding speeds, tighter windings that deliver more power in less space, reduced labor and handling. Color coding assists in conductor identification and reduces termination errors.

MWS Wire Industries custom manufactures Multifilar® Magnet Wire to assure flat, parallel construction in sizes AWG 16 and finer, and up to 20 conductors wide in some sizes.