MWS Wire /

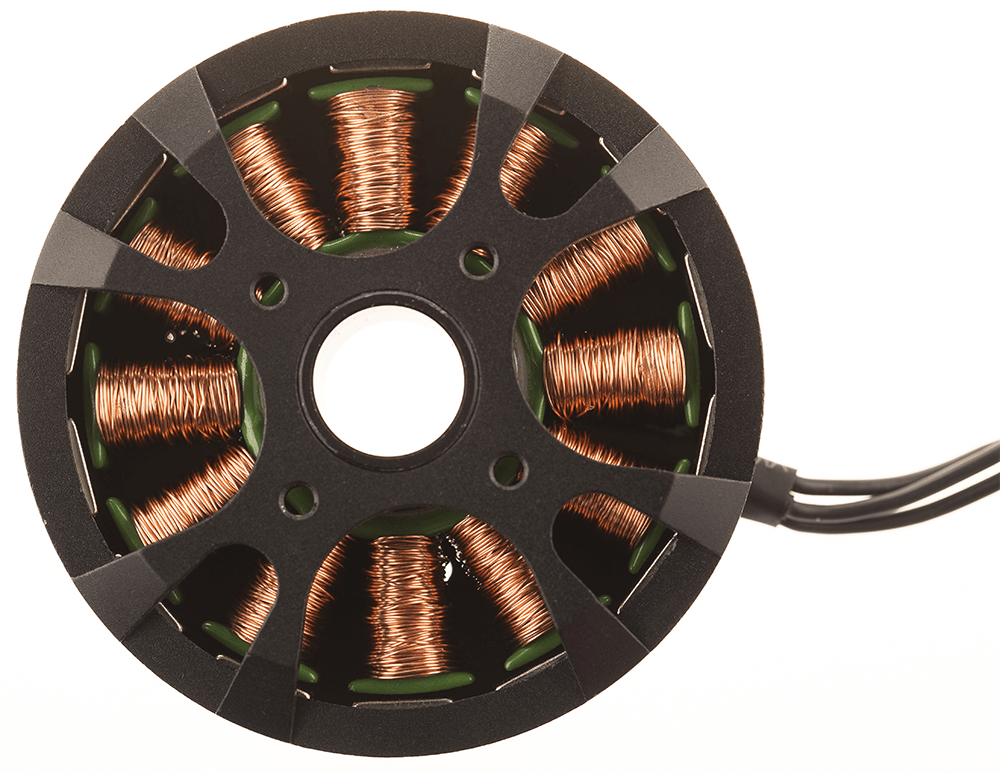

Magnet wire, also known as winding wire or enameled wire, is a copper or aluminum wire coated with a thin insulation and is a principal component of transformers, inductors, motors, and other electrical devices.

The enamel is typically a polymer film that provides a tough continuous layer of insulation. Resins used in the development of enamels are designed with wire properties in mind like abrasion resistance, solderability, and thermal rating. Enameled wires are engineered to meet temperature classes from 105 to 240°C guaranteeing service life at rated temperature for 20,000 hours.

Self-supporting coils use magnet wire with an outermost thermoplastic layer that bonds coil layers together when heated or solvent activated.

MWS offers thousands of magnet wire sizes and types to meet your application and production requirements.

Magnet Wire Insulations

Temperature Class, Type and Specification Cross Reference

| THERMAL CLASS | INSULATION TYPE | MWS PRODUCT CODE | NEMA STANDARD (NW1000) | IEC STANDARD (60317) | FEDERAL SPECIFICATION |

|---|---|---|---|---|---|

| 105° | Plain Enamel | PE | NONE | NONE | NONE |

| Formvar (RD) | F | MW 15 (RD) MW 18 (SQ & RECT) | 60317-1 (RD) 60317-17 (SQ & RECT) | JW 1177/14 (RD) JW1177/16 (SQ & RECT) |

|

| 155° | Polyurethane - 155 | P155 | MW79 | 60317-20 | JW 1177/ 41 |

| Polyurethane Nylon - 155 | PN155 | MW80 | 60317-21 | JW 1177/ 42 | |

| Polyurethane Bondable - 155 | PB155 | MW131 | 60317-35 | NONE | |

| Polyurethane Nylon Bondable - 155 | PNB155 | MW136 | NONE | NONE | |

| 180° | Polyurethane - 180 | P180 | MW82 | 60317-51 | NONE |

| Polyurethane Nylon - 180 | PN180 | MW83 | 60317-55 | NONE | |

| Polyester-imide | PT | MW30 | 60317-8 | JW 1177/ 12 | |

| Polyester-Nylon | PTN | MW76 | 60317-22 | JW 1177/ 38 | |

| Solderable Polyester | SPT | MW77 | 60317-23 | JW 1177/ 39 | |

| Solderable Polyester Nylon | SPTN | MW78 | NONE | JW 1177/ 40 | |

| Polyurethane Bondable - 180 | PB180 | MW132 | NONE | NONE | |

| Polyurethane Nylon Bondable - 180 | PNB180 | MW137 | NONE | NONE | |

| Polyester-imide Bondable | PTB | NONE | 60317-37 | NONE | |

| Polyester-amide-imide Bondable | APTB | MW102 | 60317-38 | NONE | |

| Solderable Polyester Bondable | SPTB | NONE | 60317-36 | NONE | |

| 200° | Polyester - 200 | PT200 | MW74 | 60317-42 | JW 1177/43 |

| Polyester A/ I Topcoat | APT | MW 35 (RD) MW 36 (SQ & RECT | 60317-13 (RD) 60317-29 (SQ & RECT) | JW 1177/ 14 (RD) JW1177/ 13 (SQ & RECT) | |

| Polyester A/ I Polyamideimide | APTIG | MW73 | 60317-13 | NONE | |

| 240° | Polyimide - ML* | ML | MW 16 (RD) MW 20 (SQ & RECT) | 60317-46 (RD) 60317-47 (SQ & RECT) | JW 1177/ 15 (RD) JW1177/ 18 (SQ & RECT) |