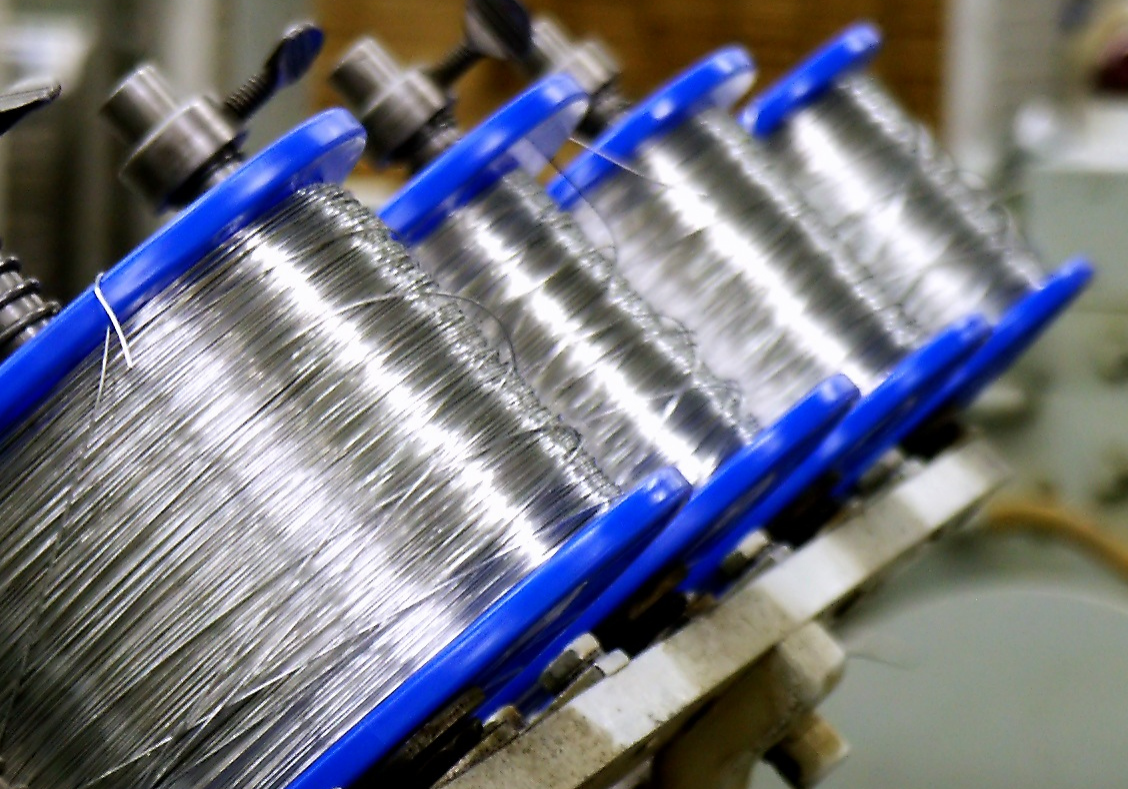

Aluminum wire's unique combination of properties make it a highly versatile material when alloyed with various metals.

Besides being light weight, characteristics of aluminum alloys include excellent workability and inherent corrosion resistance due to the inert oxide coat that forms directly after exposure to air. Many alloys in the 1000 through 5000 series are non-heat-treatable, their strength depending on the amount of cold work done.

Know what you need?

Product Spotlight

Aluminum Wire

Aluminum 1350 (EC)

UNS A91350

Aluminum 1350 is also referred to as EC (electrical conductor).

- Primary alloy utilized in aluminum magnet wire.

- Light weight, high thermal conductivity, & high mass electrical conductivity (more than twice as of Cu)

- Strong corrosion resistance

- Most film insulations are available on round aluminum wire.

Used in/for:

- Motor & transformer windings, electrical cables

- Busbars, aerospace powerlines, long distance electricity distribution.

Available in annealed and hard per ASTM B609, and extra hard per ASTM B230

Aluminum 1100

UNS A91100

Aluminum 1100 is a soft, non-heat-treatable with good corrosion resistance.

- Strength can be increased at subzero temperatures, making it an ideal low-temperature alloy.

- Addition of copper increases strength and facilitates precipitation hardening.

Used in/for:

- Electronic cables in semiconductors.

- light weight aerospace powerlines, corrosive marine/chemical applications.

Available in Annealed and hard per ASTM B211

Aluminum 1199

UNS A91199

Aluminum 1199 is the least alloyed of the commercial aluminum alloys with 99.996% Al composition.

- Excellent electrical conductivity of 64.9 IACS

- Offers good resistance to corrosion.

- Exhibits good weldability.

Used in/for:

- Welding wire

Available in Annealed and hard

Aluminum 5056

UNS A95056

Aluminum 5056 is the aluminum alloy with highest tensile strength.

- Addition of magnesium increases initial tensile strength

- manganese improves strain hardening ability

- chromium adds toughness

- Lower density than other Aluminum alloys.

Used in/for:

- Cable sheathings, hookup conductors, structural wires, rivets, screen wires

Available in annealed and hard per ASTM B211

Aluminum 6061

UNS A96061

Aluminum 6061 is a heat treatable aluminum alloy due to magnesium & silicon in its composition.

- Light weight, high conductivity, and strong resistance to corrosion

- Addition of copper increases strength and facilitates precipitation hardening.

- multi-step heat treatment for achieving max tensile strength.

Used in/for:

- Structural wire, electrical cables, busbars, welding wire

Available in Annealed and Hard per ASTM B211

Special Processes

Ask a sales representative about any special temper or wire finish.

Wire is available in sizes 14 – 44 AWG with the following options:

- Soft/Hard Temper

- Bare

- Insulated

- Shaped

- Plated

- Bondable

Aluminum Alloys Wire Data

Need more info about chemical composition? See our Data Sheet.

Looking for something specific?

We probably have it in stock. If we don’t, we can make it faster than you’d think!

Why Choose MWS?

Quick and Right Answers.

We invest heavily in our customer service and engineering team so that we can give you the right answers and the most effective customized solutions. Our success, as well as our very purpose, is directly linked to the long-term satisfaction of our customers using our wire products.

Unrivaled Availability, Low Minimum Order Quantity, and Quick Delivery.

MWS has one of the largest inventories of stainless-steel wire and other wire products. We provide wire from 1/4lb to 50lb spools. Ninety percent of our stock orders go out within a week. Short production runs and quick turnarounds are our specialty.

Pre-cut Wire Lengths and Other Custom Orders.

We can provide straight wire cuts from one inch to 6-foot lengths holding the tolerances you require for your specific application. Need shaped wire? We have a variety of special shapes including square wire, flat wire, and ribbon wire. Special coatings and finishes are available as well.

Headache Free Compliance Documentation.

Let us help you satisfy your customer’s needs for clear and comprehensive compliance documentation including RoHS, REACH, DFARS, MADE IN USA, USMCA, etc. Chemical and physical testing reports are also available upon request.

Let Us Manage Your Inventory for You.

With 40,000 sq. ft. of warehouse space and thousands of products in stock, inventory management is our specialty. It doesn’t have to be yours. Whether it’s same day shipment from inventory or producing a wire to meet just-in-time schedules, we can get what you need when you need it. Ask about scheduled shipments synchronized to work with your inventory control, JIT, or Kanban system.