MWS Wire / Home Feature /

Trends in Coil Winding call for custom wire specifications and the highest quality spooling

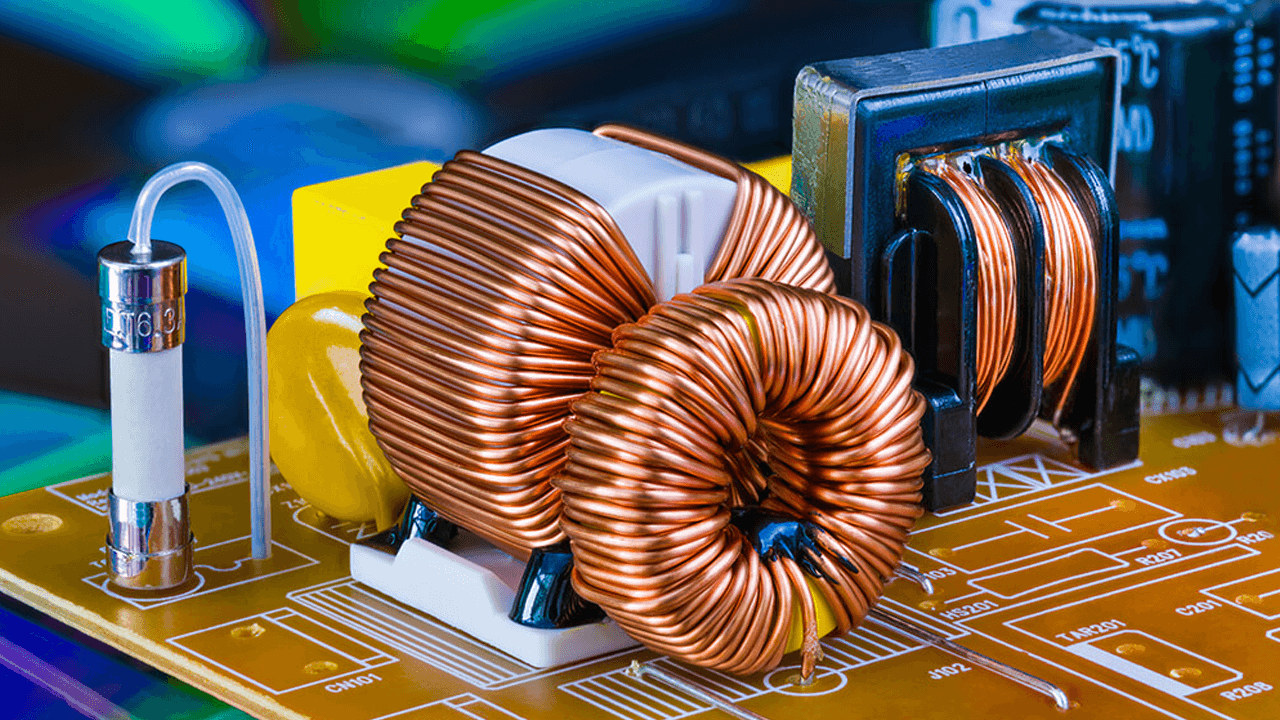

Coils provide the magnetic field of motors, transformers, and generators, and are used in the manufacturing of loudspeakers and microphones. Today, manufacturers are demanding more from their providers to attain technological advantages in the areas of efficiency, size, cost and performance. MWS is responding to those requirements with unique wire solutions produced in our plant by skilled technicians with years of experience.

Microsquare Magnet Wire®

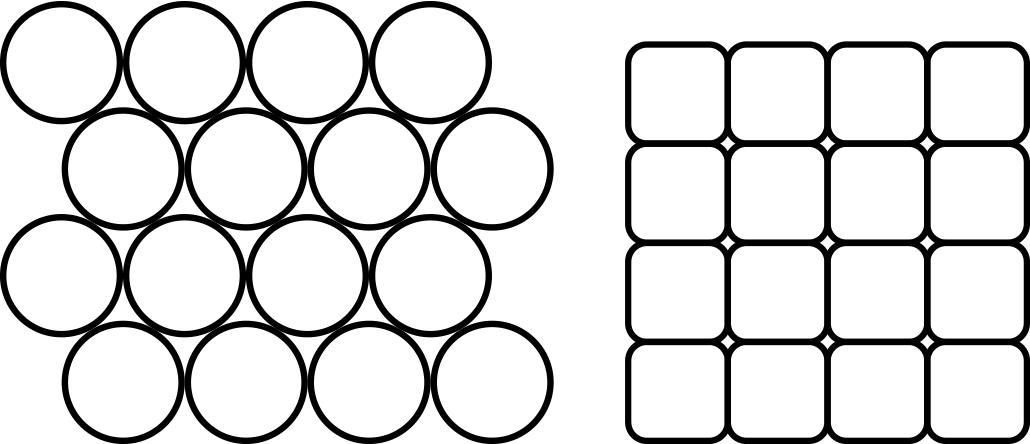

For greater efficiency and reduced heat, dense packing of wires reduces air space and enables a higher fill factor. For the tightest packing of round wires on a multi-layer winding, the wires in the upper layer are tightly wound into the grooves of the lower layer for at least 300 degrees of the coil circumference.

Square magnet wire can be wound into an even tighter coil configuration than the same amount of round wire. This enables engineers to create compact coils and small motors that deliver more power in less space.

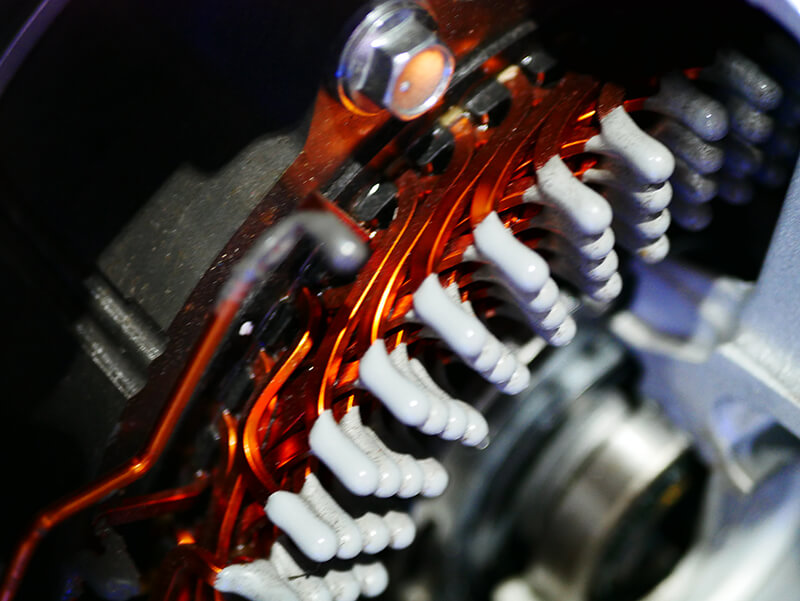

Electronically Commutated (EC) Motors

EC motors are DC brushless motors that are controlled by an external electronic circuit board. With the help of onboard electronics, the EC motor combines the best features from both AC and DC motors – delivering higher-efficiency, lower operating costs and extended service life. Once the benefits are fully understood, EC motors will become the next revolution in the electric motor industry.