Why Tin / Lead Wire for Aerospace?

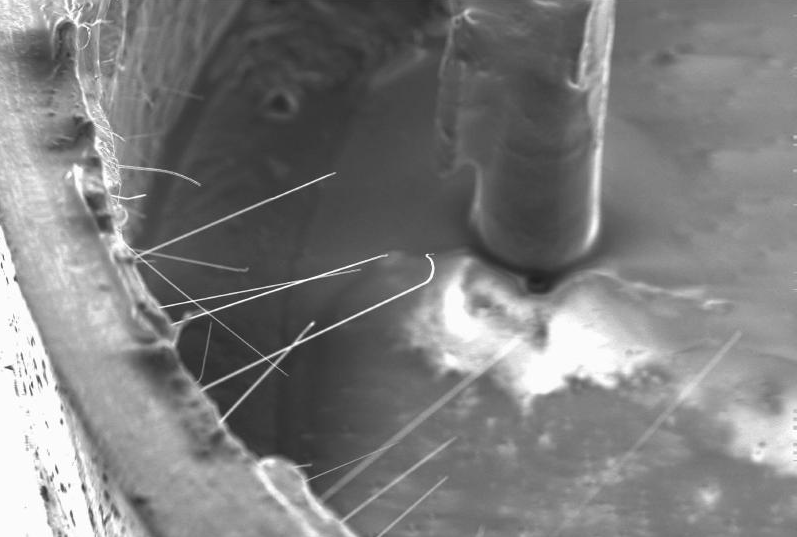

Tin/Lead plated wire offers strong electrical conductivity, corrosion resistance and an unsurpassed solderability of base metals that are not otherwise effectively soldered to. Tin/Lead plated wire works best in aeronautical and aerospace applications as the addition of lead prevents the forming of “tin whiskers”. Tin whiskers are the cause of electrical failure due to their growth and penetration of electrical cabling resulting in a short circuit.

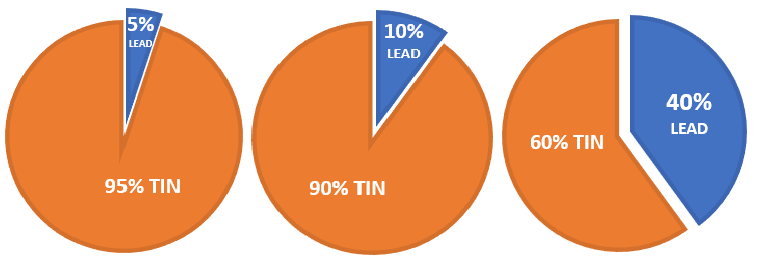

MWS offers tin/lead plated wire in both bright (die-burnished) and matte electrodeposits. The tin to lead ratios offered are 95/5, 90/10 and 60/40 respectively. This plating finish is not RoHS compliant.

The appearance of tin/lead plating is very much a function of the bare wire. If the bare wire has a matte finish, the tin plating deposit will have more of a matte luster. If the bare wire has a bright finish, the tin plating will have a more lustrous appearance. The image below shows tin whiskers growing from inside walls of a tin-plated transistor. Photo courtesy of NASA.

Tin whiskers growing from inside walls of tin-plated transistor. Photo courtesy of NASA