MWS Wire /

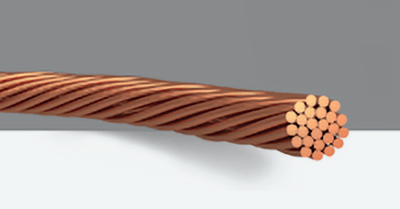

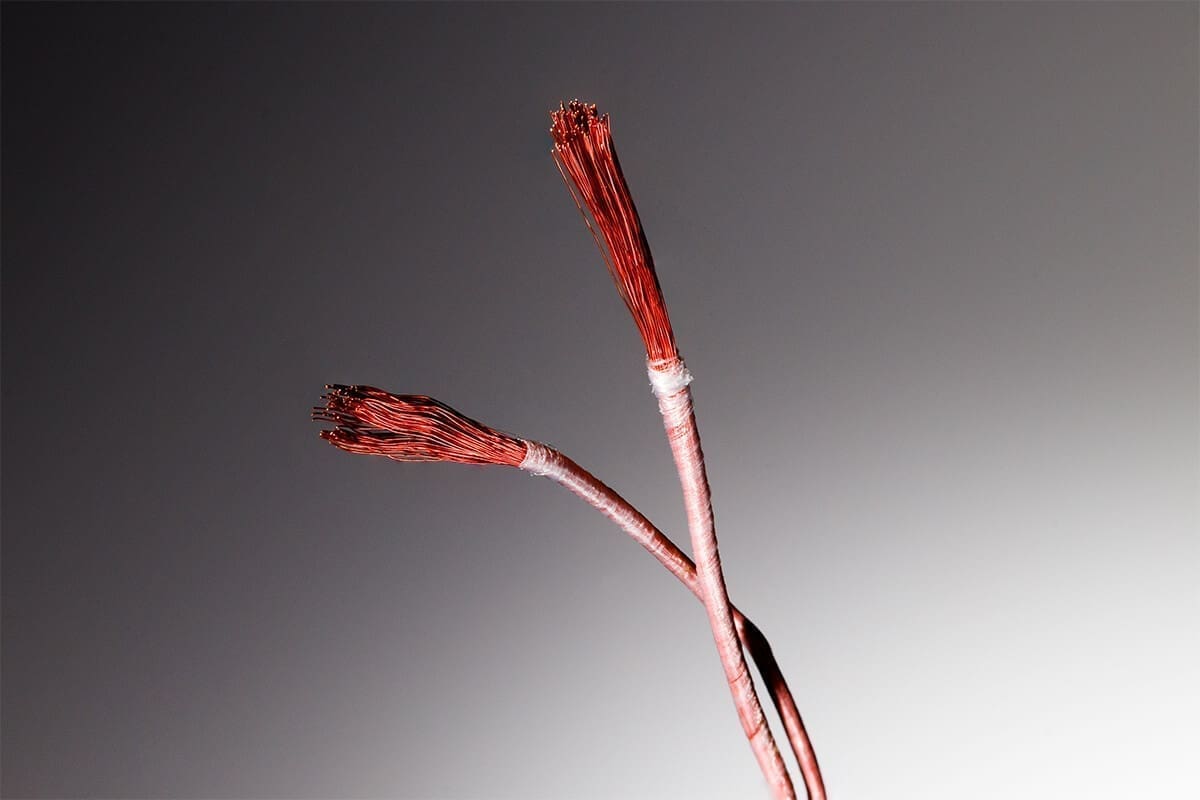

The term “Litz” is derived from the German "litzendraht" meaning woven wire. Litz wire is constructed of individually insulated magnet wires bunched or braided together in a uniform pattern so that each strand takes all possible positions in the cross section of the overall conductor.

We offer served or unserved, insulated, litz wire with a single build of polyurethane, polyurethane nylon or a heavy build of polyurethane, polyurethane nylon. We work closely with the finest manufacturers of litz wire in the U.S. to supply specialized litz wire designs for any application.

Our parent company, Elektrisola, is one of the largest producers of litz wire in the world, providing taped, high frequency litz wire for the growing EV (electric vehicle) market.

What is the benefit of Litz Wire?

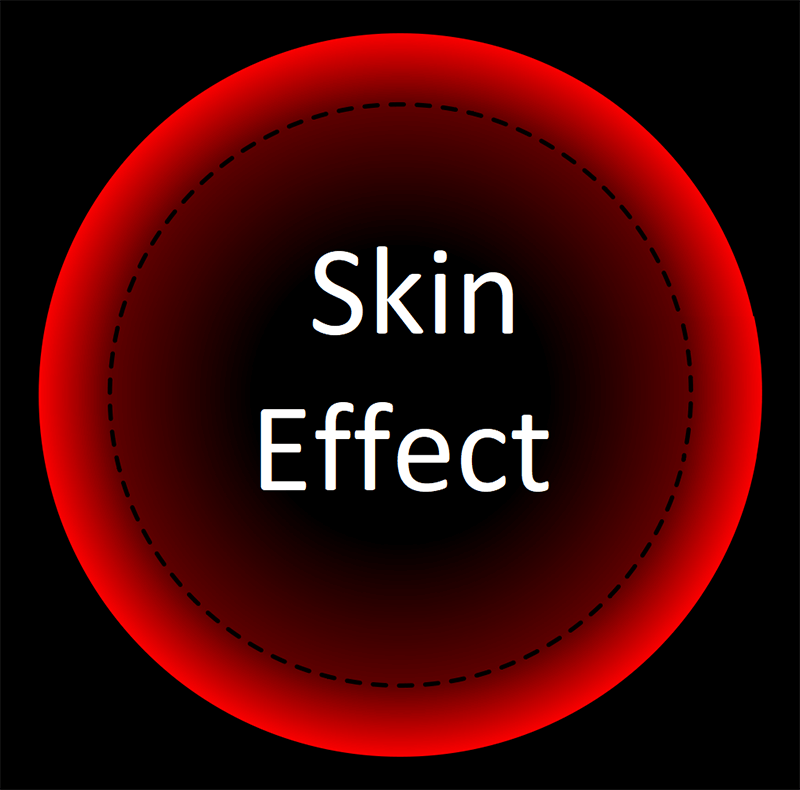

The primary benefit of litz wire is in reducing AC losses in high frequency windings due to the “skin effect”. Current in a solid conductor is concentrated at the periphery. As frequency rises, the current migrates to the skin. The multiple strand construction of litzwire allows current to divide uniformly between strands. The AC to DC resistance ratio then tends to equalize which is desirable in high-Q circuit applications.

Determining the operating frequency of the application is the most important question to consider when designing a litz wire. The operating frequency will determine both the litz construction and the gauge of the individual wire strands. The following table shows the recommended strand gauge versus frequency for most litz constructions.

Because of low electrical losses and ease of soldering, the magnet wire insulation most commonly used is polyurethane or polyurethane top coated with nylon. Litz wires are often insulated with an overall single or double wrap, or serve, of nylon textile that affords additional abrasion resistance and a space factor in the winding.

Operating frequency is the most important question to consider when specifying litz wire. The operating frequency will determine both the litz construction and the individual wire gauge. The following table shows the recommended strand gauge versus frequency for most litz constructions.

The Skin Effect causes the current density to increase exponentially from the inside to the surface.

| Frequency | Recommended Wire Gauge | Nominal Copper Diameter | Max DC Resistance (OHMS/1000FT) |

|---|---|---|---|

| 60 HZ to 1 KHZ | 28 AWG | .0126 | 66.37 |

| 1 KHZ to 10 KHZ | 30 AWG | .0100 | 105.8 |

| 10 KHZ to 20 KHZ | 33 AWG | .0071 | 211.7 |

| 20 KHZ to 50 KHZ | 36 AWG | .0050 | 431.9 |

| 50 KHZ to 100 KHZ | 38 AWG | .0040 | 681.9 |

| 100 KHZ to 200 KHZ | 40 AWG | .0031 | 1152 |

| 200 KHZ to 350 KHZ | 42 AWG | .0025 | 1801 |

| 350 KHZ to 850 KHZ | 44 AWG | .0020 | 2873 |

| 850 KHZ to 1.4 MHZ | 46 AWG | .00157 | 4544 |

| 1.4 MHZ to 2.8 MHZ | 48 AWG | .00124 | 7285 |

Applications

There is a tremendous variety of litz wire applications, from small lighting ballasts to huge wind turbines. Each with distinct technical requirements. Elektrisola not only brings many decades of experience in finding or developing the optimal wire design, it controls the entire production process ensuring quality and performance according to each customer’s specifications.

Applications

- Antenna Systems

- Bottling Equipment

- Electric & Hybrid Vehicles

- EV Charging Stations

- Electric Motors

- Florescent Lighting Ballast

- Plastic Mold Injection Machinery

- Power Transformers

- Toroidal Transformers

- Solar Inverters

- Magnetic Resonance Imaging (MRI)

- Industrial Motors

- Maglev Trains

- Medical Electronics

- Microwave Transmission

- Motor Drives

- Oil & Gas Equipment

- Specialty Audio Interconnections

- Wireless Transmission Systems

- Wind Turbines

Most popular Litz Wire configurations offered by MWS

7-28 HPN Unserved Litz

20-30 SPNSN Served Litz

40-38 SPNSN Served Litz

50-34 SPNSN Served Litz

70-36 SPNSN Served Litz

75-40 SPNSN Served Litz

100-44 SPNSN Served Litz

150-46 SPNSN Served Litz

1000-48 SPNSN Served Litz

How is Litz Wire Constructed?

Litz wire is made with individually insulated strands that range from 28 to 48 AWG. MWS’s standard magnet wire film insulations include polyurethane, polyurethane/nylon in single or heavy build. As a custom option we can provide solderable polyester, solderable polyester/nylon, polyester/polyamide-imide and polyimide – which are used to insulate each strand.

The outer insulation and the insulation on the component conductors, in some styles, may be servings or braids of nylon. Polyester heat-sealed polyester, polyimide and PTFE tape wraps along with extrusions of most thermoplastics are also available as outer insulation if the applications dictate special requirements for voltage breakdown or environmental protection.

How Litz wire “skin effect” reduces AC losses?

AC current flowing through a single wire conductor increasingly pushes the current toward the surface “skin” of the conductor as frequency increases. This physical phenomenon accelerates the wire’s AC resistance in direct proportion to the frequency of the current. Over 98% of the current will flow within a layer 4 times the skin depth from the surface. This behavior is distinct from that of direct current which usually will be distributed evenly over the cross-section of the wire.

Designers can virtually eliminate the skin effect with Litz wire. The key is to choose the diameter of individual wire strands twisted into the Litz construction that are like the skin depth for the given frequency. Doing so causes current to flow through nearly the entire cross section of each wire, thus minimizing AC resistance and heat losses.

Contact MWS Wire for Litz Wire expertise

With over fifty-five years of experience in the wire business, MWS is ISO9001: 2015 compliant and has a built solid reputation for same day shipment from our inventory or producing a wire to meet just-in-time schedules. And if we don’t have it, we can manufacture litz wire according to customer requirements.