Rewiring the Future of Automobiles

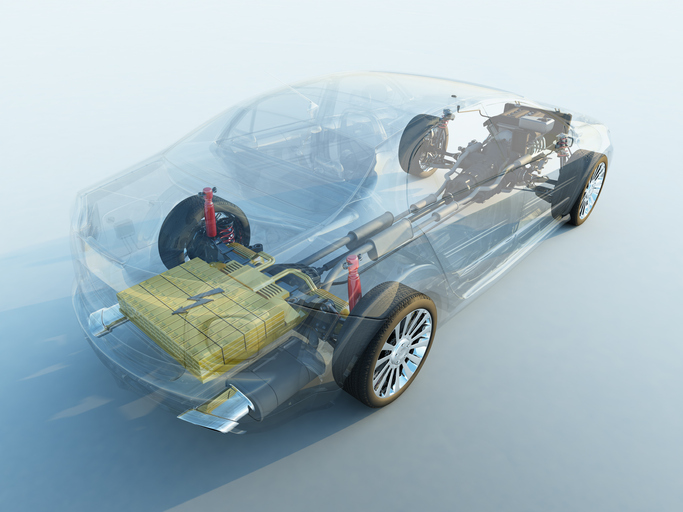

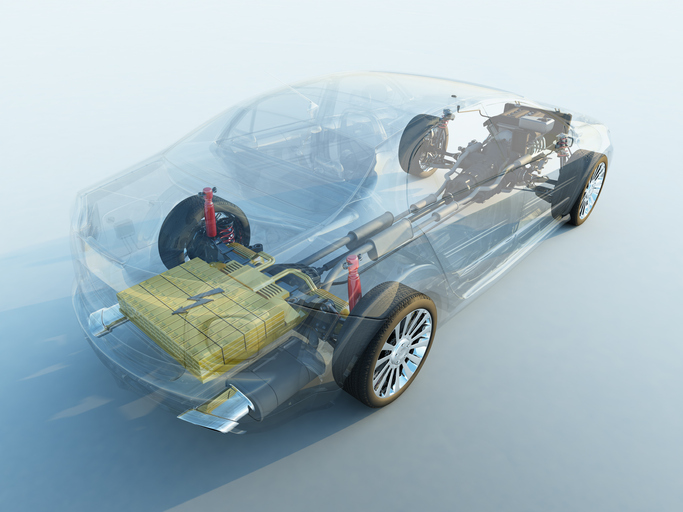

Wire has been used for many applications in the automotive industry since the 1800’s and is now being used more than ever. The applications of wire have expanded beyond just ignition circuits, sensors, gauges, lights, and radio. In present day, almost everything in the automotive industry has gone electronic, even the engine.

Gas-powered vehicles have controlled the streets for over a century, but electric vehicles are on the brink of taking the throne. Not only do electric vehicles offer a reduced carbon footprint and significantly less maintenance, they offer state-of-the-art technology and exciting acceleration. The positives are beginning to out-weigh the negatives. Electric vehicles are unquestionably the future of the automotive industry.

As a provider of unique wire solutions for the automotive industry, the electric vehicle presents quite the opportunity for MWS. Custom wire for R&D of fully electric vehicles is in demand. Magnet wire plays a crucial part in the development of electric motors and MWS maintains the worlds largest inventory of magnet wire. More power and less space is the recipe every electric car manufacturer is trying to perfect and magnetic Litz wire is the key ingredient.

Custom Litz wire will allow conductors to deliver power more effectively by increasing the surface area of the conductor without increasing its size. Litz wire is proven to be very effective when used with inverters, which convert direct current from the batteries into usable power for the vehicle. By changing the frequency of the current, inverters can manage the power output of electric motors and add extreme performance. This is one of the many reasons why proper wiring solutions are imperative to R&D of electric vehicles. As a provider of custom wire for R&D, Litz wire is the key to progression in the automotive industry.

| Type of Wire | Description |

|---|---|

| Primary wire | General purpose automotive wire. It features a multi stranded core and flexible insulation making it ideal for pulling through tight spaces. |

| Motor wire | Motor wire features finer strands of wire. This allows it to handle higher voltages. Motor wire is rated at 600 Volts with a temperature rating of 105ºC (221ºF). It is resistant to grease, oil, acids, water, and solvents. |

| SXL wire | SXL wire features a cross linked polyethylene jacket that can withstand higher heat, abrasion, and age better. It is often the preferred choice in higher stress applications like race or industrial use vehicles. |

| Speaker wire | Speaker wire is paired stranded wire intended for audio applications. It is meant to carry the 'sound' from a stereo receiver to the speakers. It is intended for low voltage use and should never be used to carry load. |

| Battery cable | Battery wire is used to connect the battery to the car’s electrical system (typically at the starter) and ground. It is larger gauge, heavier wire. |

Wire has been used for many applications in the automotive industry since the 1800’s and is now being used more than ever. The applications of wire have expanded beyond just ignition circuits, sensors, gauges, lights, and radio. In present day, almost everything in the automotive industry has gone electronic, even the engine.

Gas-powered vehicles have controlled the streets for over a century, but electric vehicles are on the brink of taking the throne. Not only do electric vehicles offer a reduced carbon footprint and significantly less maintenance, they offer state-of-the-art technology and exciting acceleration. The positives are beginning to out-weigh the negatives. Electric vehicles are unquestionably the future of the automotive industry.

As a provider of unique wire solutions for the automotive industry, the electric vehicle presents quite the opportunity for MWS. Custom wire for R&D of fully electric vehicles is in demand. Magnet wire plays a crucial part in the development of electric motors and MWS maintains the worlds largest inventory of magnet wire. More power and less space is the recipe every electric car manufacturer is trying to perfect and magnetic Litz wire is the key ingredient.

Custom Litz wire will allow conductors to deliver power more effectively by increasing the surface area of the conductor without increasing its size. Litz wire is proven to be very effective when used with inverters, which convert direct current from the batteries into usable power for the vehicle. By changing the frequency of the current, inverters can manage the power output of electric motors and add extreme performance. This is one of the many reasons why proper wiring solutions are imperative to R&D of electric vehicles. As a provider of custom wire for R&D, Litz wire is the key to progression in the automotive industry.

Edit

Type of WireDescription

Primary wireGeneral purpose automotive wire. It features a multi stranded core and flexible insulation making it ideal for pulling through tight spaces.

Motor wireMotor wire features finer strands of wire. This allows it to handle higher voltages. Motor wire is rated at 600 Volts with a temperature rating of 105ºC (221ºF). It is resistant to grease, oil, acids, water, and solvents.

SXL wireSXL wire features a cross linked polyethylene jacket that can withstand higher heat, abrasion, and age better. It is often the preferred choice in higher stress applications like race or industrial use vehicles.

Speaker wireSpeaker wire is paired stranded wire intended for audio applications. It is meant to carry the ‘sound’ from a stereo receiver to the speakers. It is intended for low voltage use and should never be used to carry load.

Battery cableBattery wire is used to connect the battery to the car’s electrical system (typically at the starter) and ground. It is larger gauge, heavier wire.

Contact a Sales Rep!