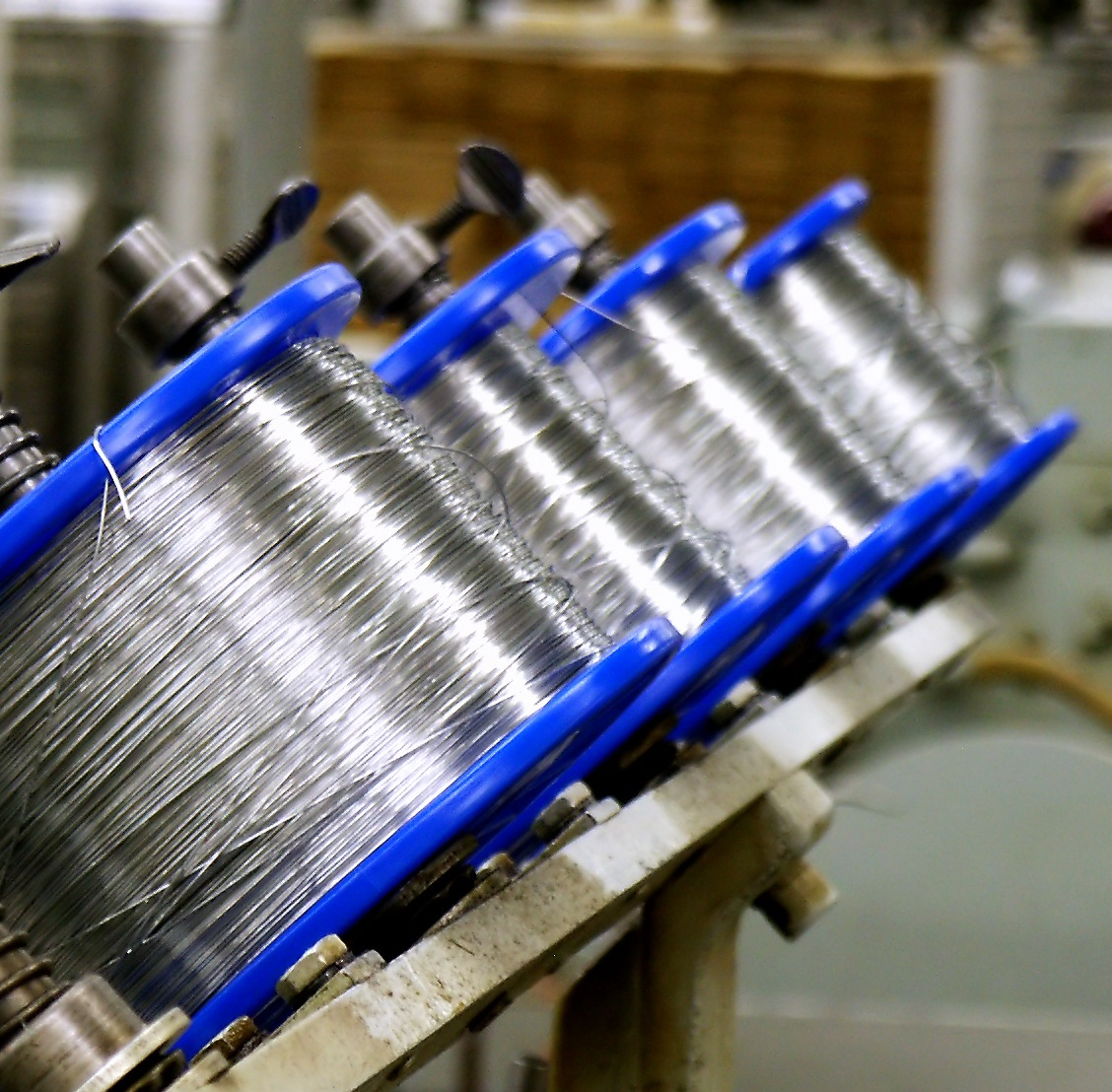

Thermistor Wire

Aluminum's unique combination of properties make it a highly versatile material when alloyed with various metals.

A thermistor is a type of resistor whose resistance depends on the temperature. The higher the temperature, the lower the resistance. We call the two fundamental types of thermistor’s PTC (Positive Temperature Coefficient), where resistance increases as temperature rises to protect against overcurrent conditions. Opposite of that, we have NTC (Negative Temperature Coefficient), where resistance decreases as temperature rises to protect against inrush overvoltage conditions.

Applications:

Thermistor’s can be seen in an assortment of electronic applications, frequently in temperature sensors. These sensors can be seen in fire prevention and security equipment, automobiles, air conditioning units, copiers/printers, and a variety of kitchen appliances. Their field of use is limited where the temperatures do not exceed 200°C, but they are preferable to more expensive thermocouples and RTD’s because of their low cost and the simple electronic circuitry that’s required.

EC Aluminum 1350

Aluminum 1350, also referred to as EC (Electrical Conductor) Aluminum, is the primary alloy utilized in aluminum magnet wire. Its combination of light weight, high thermal conductivity and high mass electrical conductivity (more than twice that of copper, per pound), make it an ideal alternative to copper for certain winding applications. Most film insulations are available on round aluminum wire.